- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

aban anigyediskɔsi werɛ an Nanhyehyaka

Product parameter .

Beae a wofi mu: Hehebei, China .

Waranti: Mfe 1 .

Mmoa a wɔayɛ no sɛnea wɔpɛ:OEM, ODM, OBM .

Nneɛma a wɔde yɛ nneɛma a wɔde yɛ nneɛma.

Nhwɛsode no nɔma:2011 .

Nneɛma a wɔde yɛ .

Pɛpɛɛpɛyɛ:Ade a wɔahyɛ da ayɛ .

Operation mode:a wɔayɛ no sɛnea wɔpɛ .

Adeɛ mu duru:Adeɛ a wɔde ayɛ adwuma .

Tumi a wɔde yɛ adwuma .

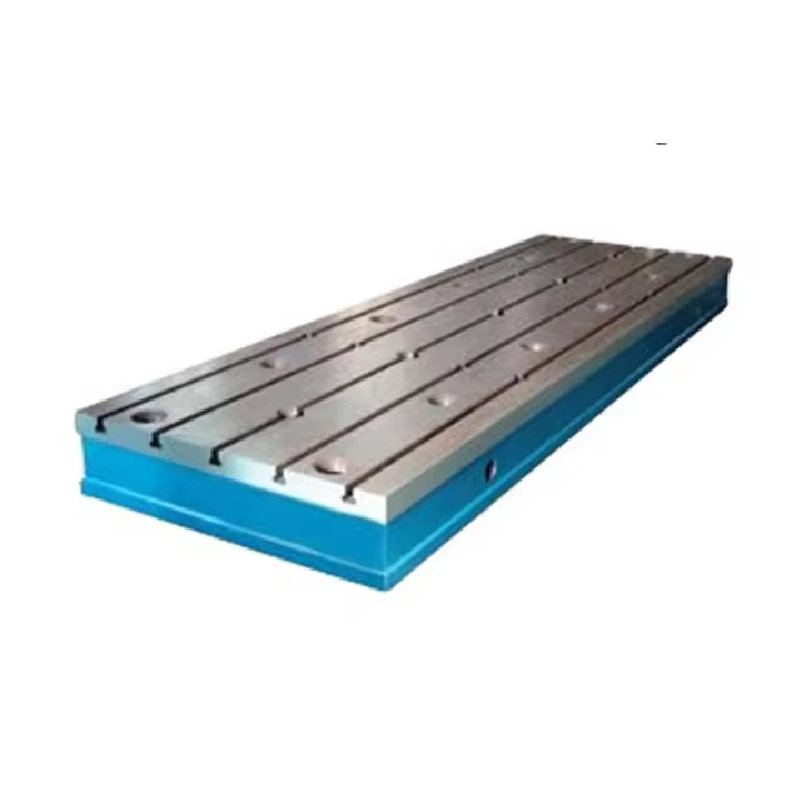

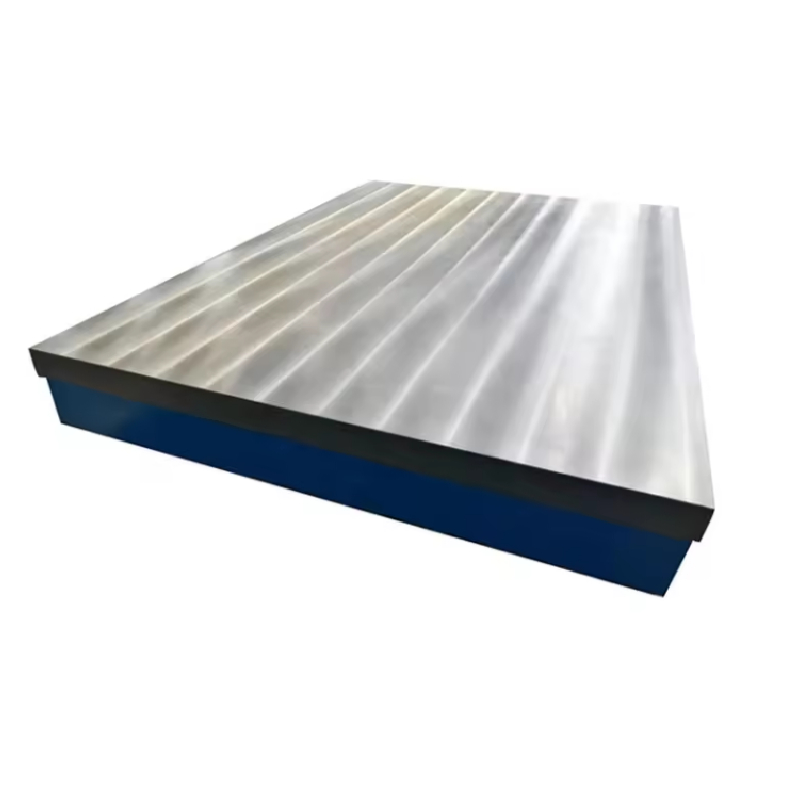

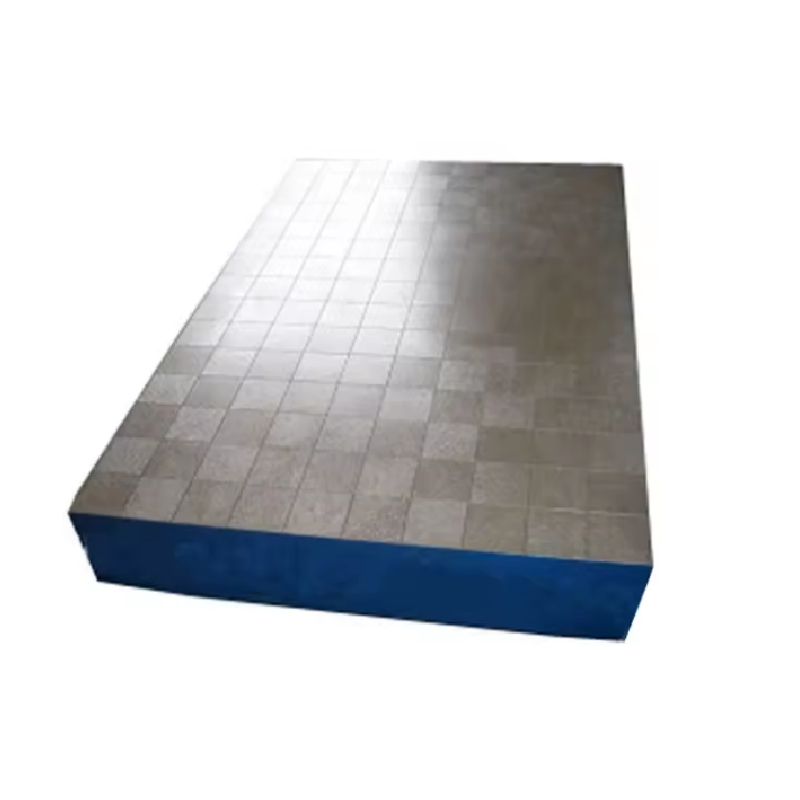

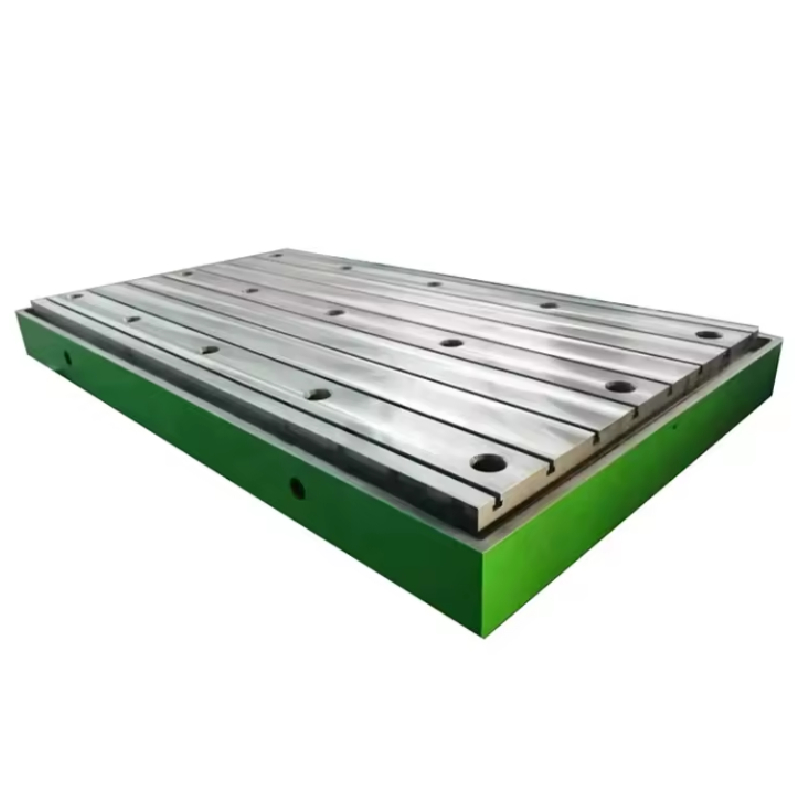

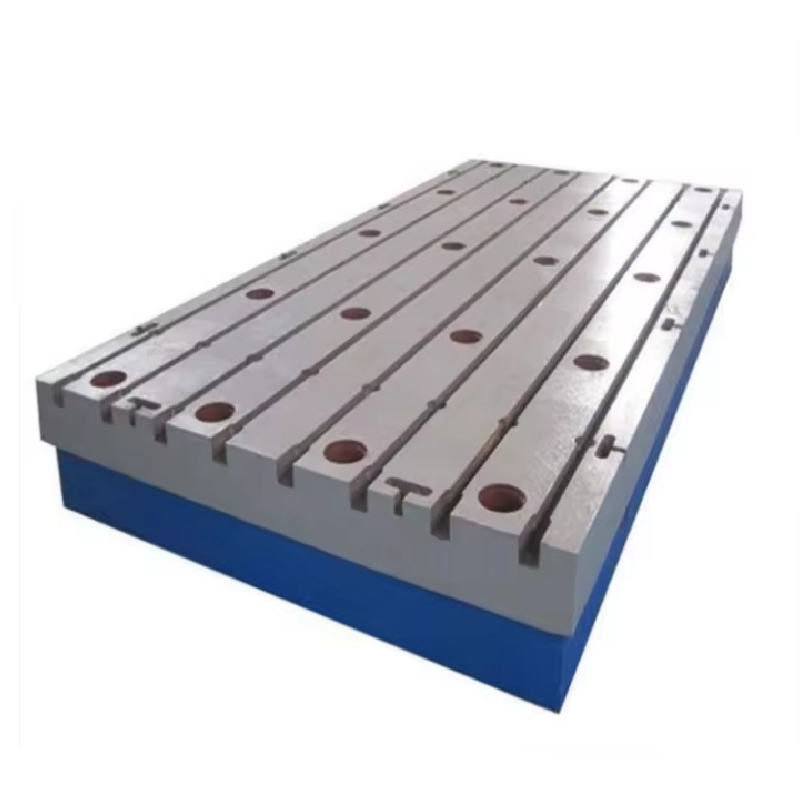

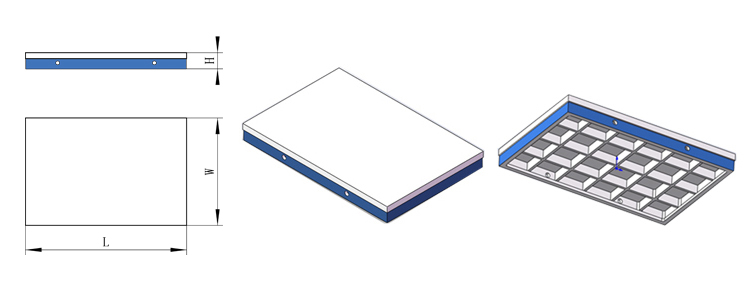

Product Name:Cast Iron no ani mprɛte .

Nneɛma:HT200-300, QT anaa dade .

Size:200×200-4000x8000mm anaasɛ customize .

Adwumayɛ soro a ɛyɛ den:HB160-240 .

Foundry nhyehyɛe:Resin anhwea a wɔde gu .

structure:rib (bone) structure a ɛwɔ ɔfasuo no mu duru a ɛdɔɔso .

Mfoniniyɛ:Primer ne anim mfonini .

pɛpɛɛpɛyɛ grade:0-3.

Adwumayɛ mu Ɔhyew:(20±55.) ℃

Nneɛma a wɔde kyekyere nneɛma: Plywood adaka .

Bere a wɔde di kan .

|

Dodow (afã horow .) |

1 – 100 |

> 100 |

|

Bere a wɔde di kan (nna .) |

30 |

sɛ wɔbɛka ho asɛm . |

Dade a emu yɛ duru a wɔde gyina hɔ .:

Wɔtaa yɛ dade gyinabea a emu yɛ duru a wɔde gyina hɔ no sɛnea ɛbɛyɛ a wɔbɛkɔ so akura nneɛma a wɔde gyina hɔ ma pɛpɛɛpɛ no mu. Leveling screws ne heavy-duty casters wɔ gyinabea ahorow no so. Ɛsɛ sɛ nneɛma a wɔkra no kyerɛ adwumayɛ sorokɔ pɔtee: efi fam kosi soro mprɛte no so.

Dɛn nti na ɛsɛ sɛ wopaw storan cast iron surface plate a wɔtɔn?

Sɛ ɛba sɛ wɔde susuw nneɛma pɛpɛɛpɛ na wɔyɛ no pɛpɛɛpɛ a, wontumi nka hia a ɛho hia sɛ wonya ɔfasu mprɛte a wotumi de ho to so no ho asɛm ntra so. Wɔ akwan horow a ɛwɔ gua so no mu no, Storan cast iron surface mprɛte no da nsow wɔ wɔn su a ɛkorɔn ne wɔn adwumayɛ ho. Ɛha yi, yɛbɛhwehwɛ nneɛma atitiriw a enti ɛsɛ sɛ yesusuw storan cast iron surface plates ho ma w’ahiade ahorow, ne akansi dade mprɛte mprɛte bo a ɛyɛ akansi no nso.

Nea edi kan koraa no, wohu STORAN cast iron surface plates sɛ ɛyɛ soronko a ɛyɛ den. Saa mprɛte yi a wɔde dade a ɛyɛ fɛ ayɛ no ma wotumi gyina ano a ɛso bi nni a ɛne warping ne wear gyina ano, na ɛma ɛyɛ pɛpɛɛpɛ bere nyinaa wɔ mmeae a ɛyɛ den sen biara mpo. Storan mprɛte a ɛyɛ den no kyerɛ sɛ wobetumi agyina sɛnea wɔde di dwuma kɛse no ano bere tenten a wɔmfa pɛpɛɛpɛyɛ mmɔ afɔre, na ɛma ɛyɛ sika a wɔde bɛto hɔ bere tenten a nyansa wom ama adwumayɛbea anaa nneɛma a wɔyɛ no tebea biara mu.

Ade foforo a ɛho hia a ɛsɛ sɛ yesusuw ho ne storan cast iron no ani mprɛte a wɔde wie pɛpɛɛpɛ no. Wɔde mfiri ayɛ mprɛte biara yiye na ama wɔatumi ayɛ petee a edu nnwuma gyinapɛn a emu yɛ den ho. Saa pɛpɛɛpɛyɛ gyinabea yi ho hia ma application ahorow a susudua pɔtee ho hia, na ɛma wɔn a wɔde di dwuma no tumi de ahotoso yɛ wɔn adwuma.

Sɛ wɔreka cast iron surface plate price ho asɛm a, Storan de akansi bo a ɛne wɔn nneɛma no su ne ne dwumadi hyia ma. Sɛ wode sika hyɛ storan cast iron surface plate mu a, ebetumi ama woabɔ ka mfiase no, nanso mfaso a ɛwɔ so bere tenten wɔ sɛnea ɛbɛkɔ so atra hɔ akyɛ na wɔayɛ no pɛpɛɛpɛ no mu no, akyinnye biara nni ho sɛ ɛboro saa ka a wɔbɔ ansa na wɔabɔ no so. Bio nso, Storan de akɛseɛ ne nhwɛsoɔ ahodoɔ ma de di ahwehwɛdeɛ ahodoɔ ho dwuma, ɛma nnwuma nya kwan a ɛyɛ pɛpɛɛpɛ ma wɔn ahiadeɛ pɔtee a wɔmfa wɔn ho nhyɛ sikasɛm nhyehyɛeɛ mu.

Sɛ yɛde rewie a, Storan cast iron surface plate a wɔbɛpaw no yɛ gyinaesi a nyansa wom ma obiara a ɔrehwehwɛ ahotoso, pɛpɛɛpɛyɛ, ne bo a ɛsom. Ɛnam sɛ ɛyɛ papa sɛ wobɛkari pɛ wɔ quality ne akansi cast iron surface plate price nti, Storan hwɛ hu sɛ wo susudua ne machining nnwuma no yɛ executed a mfomso biara nni ho. Hwɛ sɛ wo dwumadi ahorow no renhinhim da denam nea nyansa wom a wobɛpaw sɛ wode sika bɛto Storan mu no so.

mprɛte a ɛwɔ soro: granite vs dade a wɔde gu .

Dade a wɔde ayɛ mprɛte a ɛwɔ soro .

Wɔde mprɛte a wɔde dade ayɛ no adi dwuma mfe du du pii wɔ mfiridwuma mu. Mfaso titiriw biako a ɛwɔ dade a wɔde ayɛ mprɛte a wɔde gu so no so ne sɛnea ɛyɛ den. Wonim dade a wɔde ayɛ no sɛ etumi gyina nnesoa a emu yɛ duru ano a enni deforming, na ɛma ɛyɛ nea eye sen biara a wobetumi apaw ama mfiridwuma ne nea wɔde yɛ nneɛma. Bio nso, n’abɔde mu nsu a ɛyɛ damping no boa ma wɔtwe wosow, a ebetumi ama susudua no pɛpɛɛpɛyɛ ayɛ kɛse.

Nanso, dade a wɔde ayɛ mprɛte a wɔde gu so no de wɔn ankasa anohyeto ahorow ba. Bere a mpɛn pii no ne bo nyɛ den te sɛ granite mprɛte no, sɛ wɔanhwɛ so yiye a, ɛyɛ mmerɛw sɛ ɛbɛhyew na asɛe nso. Saa ade yi betumi asiw wɔn nkwa nna ano na ayɛ nea ɛho hia sɛ wɔhwɛ so mpɛn pii. Bio nso, dade mprɛte a wɔde gu mu no hwehwɛ sɛ wɔtwetwe no daa na ama wɔatumi akura mu, na ebetumi agye bere pii na ebetumi ahwehwɛ sɛ adwumayɛfo a wɔn ho akokwaw no ho akokwaw.

Granite mprɛte a ɛwɔ soro .

Granite mprɛte a ɛwɔ soro . reyɛ agye din kɛse wɔ nnɛyi nneɛma a wɔyɛ ne nhwehwɛmu ho nhyehyɛe mu esiane mfaso pii a wonya nti. Mfaso titiriw biako a ɛwɔ granite soro mprɛte so ne sɛnea ɛko tia nneɛma a atwa yɛn ho ahyia te sɛ nsu ne ɔhyew mu nsakrae. Nea ɛnte sɛ dade a wɔde gu mu no, granite ntumi nkata so anaasɛ ɛyɛ mmerɛw, na ɛma ɛyɛ nea eye sen biara a wobetumi apaw ama bere tenten a wɔde bedi dwuma.

Granite soro mprɛte nso hoahoa ne ho sɛ ɛyɛ flatness a ɛkorɔn na ɛyɛ den bere a wɔde toto wɔn mfɛfo dade a wɔde ayɛ no ho no. Nneɛma a wɔyɛ ma granite mprɛte no ma kwan ma wɔyɛ pɛpɛɛpɛ na ɛyɛ pɛpɛɛpɛ, a ɛho hia kɛse ma nnwuma a ɛho hia a wɔde susuw nneɛma. Bio nso, granite wɔ ahoɔden soronko a ɛyɛ den, a ɛboa ma ɛtra hɔ kyɛ na ɛho asɛe kakraa bi bere a bere kɔ so no.

Nea enye wɔ ho no, granite mprɛte a ɛwɔ soro no betumi ayɛ nea ne bo yɛ den sen dade a wɔde gu mu a wobetumi apaw. Wɔn nso yɛ brittle kɛse, a ɛkyerɛ sɛ wobetumi abubu anaasɛ wɔbɛpaapae mu sɛ wɔde wɔn ho hyɛ nkɛntɛnso a ɛtra so anaasɛ adwennwen mu a. Enti, ɛho hia sɛ wɔde ahwɛyiye di dwuma na ama granite mprɛte no atra hɔ akyɛ.

Wɔ akyinnyegye a ɛda dade a wɔde gu so mprɛte ne granite mprɛte ntam no mu no, nea wobɛpaw no gyina nea wode di dwuma pɔtee, sikasɛm nhyehyɛe, ne nea wopɛ sɛ wusiesie so kɛse. Sɛ wopɛ mprɛte a ɛyɛ den a ebetumi agyina nnesoa a emu yɛ duru ano na ɛnhaw wo sɛ wobesiesie nneɛma foforo a ɛka ho no a, ebia dade a wɔde gu so a wɔde gu so no bɛyɛ nea ɛfata ama wo. Ɔkwan foforo so no, sɛ wohwehwɛ pɛpɛɛpɛyɛ a ɛkorɔn, nsiesie a ɛso tew, ne nkwa tenten a ɛkyɛn so a, granite mprɛte bɛyɛ ɔkwan a ɛfata kɛse.

Efi 200×200 kosi 4000x8000mm: sɛnea yɛn dade a wɔde ayɛ no ani mprɛte no dannan ne ho ma ɛne nnwuma nyinaa mu nhwehwɛmu ahiade hyia .

Storaen cast iron surface mprɛte no san yɛ versatility wɔ mfiridwuma metrology mu, a ɛma kɛse a ɛso bi nni —efi compact 200x200mm benkyi so kosi 4000x8000mm platform akɛse so —a ɛyɛ nea ɛnyɛ hwee wɔ nhwehwɛmu, agyiraehyɛde, ne calibration ahiade ahorow ho wɔ nneɛma a wɔyɛ, nneɛma a wɔyɛ, ne mfiridwuma mu. Wɔayɛ no yiye fi premium HT200-300 cast iron (HB160-240 hardness) a adwennwen-relieved adansi, yɛn cast dade nnyinaso mprɛte ne dade fabrication tables ka pɛpɛɛpɛ, rigidity, ne customizable afã horow de yɛ akyi dompe a ɛyɛ papa sohwɛ wɔ applications a efi micro-precision to heavy-duty-duty-duty-duty-duty-duty-duty-duty.

Wɔayɛ no kɛse ama adwumayɛ nsenia biara .

Micro-precision & bench-top a wɔde di dwuma (200×200–1000x1000mm .)

Eye ma ɛlɛtrɔnik mfiri, dɔn yɛ, ne nnuruyɛ mfiri a wɔyɛ, na saa dade a wɔde ayɛ nneɛma nketenkete a wɔde yɛ nneɛma no ma ɛyɛ gyinapɛn a ɛyɛ den ma nneɛma nketenkete te sɛ nhama anaa gya nnaka a wɔde hwɛ nneɛma mu. Wɔn asase a ɛyɛ fɛ (RA1.6–3.2μm) ne 0–1 class precision (flatness ≤0.02mm/1000mm) hwɛ ma micron-level pɛpɛɛpɛyɛ, bere a lightweight design (15–50kg) ma ɛyɛ mmerɛw sɛ wɔde bɛka lab benkyi anaa CNC mfiri a ɛbɛn insepction ho.

Engineering & Modular nhyehyɛe ahorow nyinaa (1000×1500–2000x3000mm .)

Adwumayɛ pɔnkɔ a wɔde mfiri yɛ adwuma no, saa mfinimfini mprɛte yi di mu wɔ afã horow a ɛyɛ mfinimfini a ɛyɛ nokware no mu—efi kar engine a wɔde ayɛ nneɛma mu kosi hydraulic valve ahorow so. Wɔde ribbed ribbed undersides ahyɛ mu den, wogyina static loads a ɛkɔ 2000kg/m2 ano, na ɛma ɛyɛ pɛpɛɛpɛ sɛ steel fabrication tables ma welding fixture alignment anaa CNC mfiri calibration. T-slots a wopɛ (ISO 2571 gyinapɛn) ne threaded holes (M8–M24) ma wotumi yɛ nsakrae, na ɛma wotumi kyekyere gauges, fixtures, anaa laser alignment nnwinnade ntɛmntɛm.

Nnwuma a emu yɛ duru ne nnwuma akɛse a ɛboro so (2500×4000–4000x8000mm .)

Ahunmu nneɛma a wɔde yɛ dan no mu nneɛma, mfiri a emu yɛ duru, anaa po so ahyɛn afã horow no, yɛn dade nnyinaso mprɛte akɛse a wɔde ayɛ no ma ɛyɛ den a ɛnyɛ nea ɛyɛ hu. Wɔn ano a ɛyɛ den (50–80mm) ne dennse HT300 nneɛma no gyina deformation ase wɔ 3000kg + adesoa ase, bere a stress-relief annealing (a wɔde ayɛ 550°C nnɔnhwerew 4) yi nhyɛso a ɛwɔ wɔn mu no fi hɔ, na ɛma ɛyɛ den sɛ ɛbɛyɛ flatness stability wɔ mmeae a wɔyɛ hyew kɛse mpo. Saa mprɛte yi taa yɛ nneɛma a wɔde si hɔ daa ma mfiri a wɔde susuw nneɛma a wɔde susuw nneɛma (CMM) anaasɛ robɔt welding nkwammoaa, na ɛma wotumi de wɔn ho to so sɛ wɔde bɛyɛ nhwehwɛmu wɔ mill-scale mu.

Customization ma application ahwehwɛde soronko .

Beyond standard sizes, yɛde ano aduru a wɔahyɛ da ayɛ ma a ɛbɛma yɛadi ahiade pɔtee bi ho dwuma .:

Aduru a wɔde yɛ nneɛma a ɛwɔ soro: Paw fi paint a ɛko tia rust (a ɛfata ma mmeae a ɛhɔ yɛ nwini), epoxy coatings (nnuru a ɛko tia), anaasɛ nneɛma a wɔayɛ no yiye kɛse (Ra0.8μm ma metrology labs).

Structural enhancements: Fa reinforced corner brackets ka ho ma forklift handling, recessed mounting zones ma automated equipment, anaasɛ beveled edges ma ahobammɔ operator kwan wɔ tight adwumayɛbeas.

Multi-platform integration: Bolt bom dadeɛ a wɔde yɛ nneɛma pii a wɔde pɛpɛɛpɛ alignment pins di dwuma, na ɛma nsɛm a wɔatrɛ mu a ɛnyɛ den a wɔde yɛ nhyiamu a ɛsõ dodo —a ɛtaa ba wɔ kuayɛ mfiri anaa ngo rig component a wɔyɛ mu.

Wo kɔ-kɔ ano aduru ma nhwehwɛmu nsenia biara .

Sɛ́ ebia wuhia dade a wɔde ayɛ ade a ɛyɛ ketewaa bi a wɔde yɛ prototyping, dade a wɔde yɛ mfinimfini a ɛyɛ mfinimfini a wɔde yɛ batch, anaasɛ dade a wɔde ayɛ adwuma a wɔde yɛ adwuma wɔ mfiridwuma mu a wɔde yɛ nneɛma a wɔde yɛ adwuma no, Storaen kɛse ne akwan a wɔfa so yɛ no sɛnea ɛfata no hwɛ hu sɛ ɛfata pɛpɛɛpɛ. Ɛdenam ahotoso a enni bere mu a ɛwɔ dade a wɔde gu mu ne mfiridwuma mu nsakrae a wɔde ka bom so no, yɛma wɔn a wɔyɛ nneɛma no tumi ma wodi nhwehwɛmu asɛnnennen biara ho dwuma—efi ade ketewaa bi so kosi ɔdan kɛse no so —ne ahotoso wɔ wɔn susuw gyinapɛn no mu. Hwehwɛ yɛn nyinaa mu nnɛ na hu nea enti a pɛpɛɛpɛyɛ nni kɛse anohyeto biara.

Mfiridwuma mu nhwehwɛmu a wɔyɛ ho ano aduru Ɛyaw nsɛntitiriw: sɛnea dade a wɔde gu so mprɛte a wɔde ayɛ adwuma no yi mfomso fi adwuma mu .

Wɔ mfiridwuma mu mfiridwuma mu no, nsusuwii a ɛne ne ho nhyia, nhyehyɛe a egye bere pii, ne nsɛm a wɔde gyina hɔ ma a wontumi mfa ho nto so no haw wɔn a wɔhwɛ so yiye no—kosi sɛ Storaen dade a wɔde ayɛ no ani mprɛte no hyɛn mfonini no mu. Wɔayɛ no sɛnea ɛbɛyɛ a ɛbɛsakra nhwehwɛmu adwumayɛ nhyehyɛe ahorow no, yɛn dade a wɔde ayɛ nnyinaso mprɛte ne dade a wɔde yɛ nneɛma pon no di ɛyaw nsɛntitiriw no ho dwuma pɛpɛɛpɛ, ɛyɛ den, na wotumi yɛ nsakrae, na ɛhwɛ hu sɛ wɔde ahotoso hu adwuma no mu sintɔ biara.

Ɛyaw nsɛntitiriw 1: gyinabea a ɛnteɛ a ɛde kɔ adwuma a wɔsan yɛ mu .

Sotɔɔ pii di aperepere wɔ susudua nnyinaso a entumi nnyina a ɛde gauges a ɛnteɛ ne atoro pass/fail aba no ba no ho. Storaen dade a wɔde ayɛ no ani mprɛte (HT200-300 ade, HB160-240 a ɛyɛ den) ma wonya fapem a ɛyɛ den .:

Stress-relieved stability: Wɔde annealed wɔ 550°C nnɔnhwerew 4, fi mu casting stresses yi fi hɔ, siw warping a ebetumi ayɛ skew akenkan —critical for precision tasks te sɛ CNC mfiri calibration anaa gearbox flatness checks.

Micron-level flatness: Ɛnam sɛ pɛpɛɛpɛyɛ grades fi 0 (0.02mm/1000mm flatness) kosi 3 (0.1mm/1000mm nti), saa mprɛte yi de nokware planar reference a ɛma deviations nketewa te sɛ 20 microns (0.02mm) a wotumi hu ma, hwɛ hu sɛ sintɔ biara nni hɔ a wɔankɔ so.

Ɛyaw Point 2: Setups a ɛnyɛ adwuma yiye a wɔde yɛ adwuma ahorow ahorow .

Ɛnsɛ sɛ nsakrae a ɛba nkitahodi nketewa ne mfiri akɛse ntam no hwehwɛ sɛ wɔde pon pii di dwuma. Yɛn dade a wɔde yɛ nneɛma a wɔde yɛ nneɛma no siesie eyi .:

Modular versatility: A grid of optional T-slots (ISO 2571) ne threaded holes (M8–M24) ma kwan ma wɔkyekyere angle plates, height gauges, anaa magnetic fixtures ntɛmntɛm, ɛtew nhyehyɛe bere so 50% sɛ wɔde toto nneɛma a wɔanhyehyɛ no ho a.

Size for every scale: Efi 200x200mm benkyi ma micro-components kosi 4000x8000mm platforms ma mfiri a emu yɛ duru, mprɛte biara ribbed understructure boa 15kg kosi 300kg adesoa a enni deflection, yi hia a ehia ma makeshift mmoa a ɛma pɛpɛɛpɛ pɛpɛɛpɛ.

Ɛyaw Point 3: Nsiesiei a ɛkɔ soro ne nkwa nna tiaa .

Atetesɛm mu susudua so nneɛma a ɛwɔ hɔ no sɛe bere kɔ so esiane sɛ asɛe anaasɛ asɛe nti, nanso yɛn dade a wɔde gu fam mprɛte no de adwumayɛ a ɛtra hɔ daa ma .:

Durability by design: Aburow a ɛyɛ den a ɛwɔ HT200 cast iron no mu no gyina nsensanee ne ntini a ɛwɔ mu fi gauge contact a ɛtaa ba no ano, bere a paint anaa epoxy coatings a wɔpaw a wopɛ no bɔ ho ban fi coolant a ɛhwie gu ne mmeae a ɛhɔ yɛ nwini no ho —ɛtrɛw ɔsom asetra mu 20% sɛ wɔde toto akwan foforo a wɔanhyɛ no ho a.

Nneɛma a ɛho ka sua a wɔbɛhwɛ so yiye: Nea ɛnte sɛ granite mprɛte a ɛpaapae wɔ nkɛntɛnso ase anaasɛ ɛho hia sɛ wɔde di dwuma yiye no, yɛn dade a wɔde gu so no betumi asan ayɛ fam de asan ayɛ pɛpɛɛpɛ, na ɛde ano aduru a ɛho ka sua ma adwumayɛbea ahorow a kar pii wom.

Nea enti a Storaen cast dade ani mprɛte di mu .

Mmara a wɔdi soɔ a wɔansiesie: Wɔagye atom sɛ ISO 9001 ne JB/T7974-99, mprɛte biara wɔ nhwehwɛmu amanneɛbɔ a wɔtumi hwehwɛ mu, a ɛhwɛ ma wɔgye tom wɔ kar, ahunmu, ne mfiri a emu yɛ duru a wɔde yɛ nhwehwɛmu.

Amanneɛbɔ a ɛfa ahiade soronko ho: Wohia prɛte a ɛwɔ mmeae a wɔde si a wɔde robɔt nsa ahyɛ mu anaasɛ anoano a ɛyɛ bevel ama nea ɔde di dwuma no ahobammɔ? Yɛn kuw no ntadepam nsusuwii, soro awie (Ra1.6–3.2μm), ne structure features ma ɛne wo adwumayɛ hyia —adwuma biara nni hɔ a ɛho nhia.

Dane nhwehwɛmu ti a ɛyɛ yaw no yɛ ahotoso a ɛwɔ so sɛ wobɛhwɛ so yiye .

Sɛ́ ebia worehwɛ sɛnea hydraulic manifold bi yɛ petee, wode drill points hyɛ dade a wɔde ayɛ no agyirae, anaasɛ woresusuw CMM bi ho no, Storaen dade a wɔde ayɛ no ani mprɛte no yi nsusuwii hunu no fi hɔ. Ɛdenam nhwɛsode a ɛyɛ den, ɛyɛ pɛpɛɛpɛ, na ɛtra hɔ kyɛ a wɔde ma so no, wɔdannan nhwehwɛmu mu nsɛnnennen a ɛyɛ abasamtu sen biara no ma ɛbɛyɛ nneɛma a ɛyɛ mmerɛw, a wotumi de ho to so —enti wubetumi de w’adwene asi nea ɛho hia so: nneɛma a mfomso biara nni ho a wode bɛma, bere biara.

Fa dade nnyinaso mprɛte anaa dade a wɔde yɛ pon a wɔasisi no sɛnea ɛbɛyɛ a ɛbɛboro so no bɛma wo su sohwɛ no ayɛ yiye. Hwehwɛ yɛn range nnɛ na hwɛ sɛnea precision engineering di machining pain points a ɛyɛ den sen biara mpo ho dwuma.

Product Specifications .

Nneɛma: HT200-300 specification: 200×200-4000x8000mm anaasɛ customized adwumayɛbea: flat, grid slots ma beae, tapped holes, T-slots hardness a adwumayɛbea no yɛ den: HB160-240 Surface treatment treatment treatment pɛpɛɛpɛ Face Paint Surface Coating: Adwumayɛbea a wɔde ngo a wɔde picking ngo akata so ne nea ɛnyɛ adwuma a wɔde antirust paint akata so Ɔhyew a wɔde ayɛ aduru: Ɛwɔ hɔ, ma adwennwen ano aduru gyinabea: Ɛwɔ hɔ ma ne kɛse a ɛne no hyia pɛpɛɛpɛ: 0-3 Adwumayɛ hyew: (20±5) °C Nneɛma a wɔde kyekyere nneɛma: Plywood Box

Product parameter .

|

Daabi. |

Ne tɛtrɛtɛ x tenten-mmm .) |

pɛpɛɛpɛyɛ grade . |

|||

|

|

|

0 |

1 |

2 |

3 |

|

|

|

Flatness . (μm .) |

|||

|

1 |

200X200 |

3.5 |

7 |

14 |

|

|

2 |

300X200 |

4 |

8 |

15 |

|

|

3 |

300X300 |

4 |

8 |

15 |

|

|

4 |

300X400 |

4 |

8 |

16 |

|

|

5 |

400X400 |

4.5 |

8.5 |

17 |

|

|

6 |

400X500 |

4.5 |

9 |

18 |

|

|

7 |

400X600 |

5 |

10 |

19 |

|

|

8 |

500X500 |

5 |

10 |

19 |

|

|

9 |

500X600 |

5 |

10 |

19 |

|

|

10 |

500X800 |

5.5 |

11 |

21 |

|

|

11 |

600X800 |

5.5 |

11 |

22 |

|

|

12 |

600X900 |

6 |

11.5 |

23 |

|

|

13 |

1000X750 |

|

12.5 |

25 |

50 |

|

14 |

1000X1000 |

|

13.5 |

27 |

54 |

|

15 |

1000X1200 |

|

14 |

29 |

58 |

|

16 |

1000X1500 |

|

16 |

32 |

63 |

|

17 |

1000X2000 |

|

18.5 |

37 |

74 |

|

18 |

1500X2000 |

|

20 |

40 |

80 |

|

19 |

1500X2500 |

|

22.5 |

45 |

90 |

|

20 |

1500X3000 |

|

25 |

50 |

100 |

|

21 |

2000X2000 |

|

22 |

44 |

88 |

|

22 |

2000X3000 |

|

27 |

53 |

106 |

|

23 |

2000X4000 |

|

32 |

64 |

127 |

|

24 |

2000X5000 |

|

37 |

75 |

150 |

|

25 |

2000X6000 |

|

43 |

86 |

172 |

|

26 |

2000X7000 |

|

49 |

97 |

194 |

|

27 |

2000X8000 |

|

54.5 |

109 |

218 |

|

28 |

2500X3000 |

|

28.5 |

57 |

114 |

|

29 |

2500X4000 |

|

33 |

67 |

133 |

|

30 |

2500X5000 |

|

39 |

77 |

154 |

|

31 |

2500X6000 |

|

|

88 |

176 |

|

32 |

2500X7000 |

|

|

99 |

198 |

|

33 |

2500X8000 |

|

|

110 |

221 |

|

34 |

3000X3000 |

|

|

61 |

122 |

|

35 |

3000X4000 |

|

|

70 |

140 |

|

36 |

3000X5000 |

|

|

80 |

160 |

|

37 |

3000X6000 |

|

|

90.5 |

181 |

|

38 |

3000X7000 |

|

|

101 |

203 |

|

39 |

3000X8000 |

|

|

112.5 |

225 |

|

40 |

4000X4000 |

|

|

78 |

156 |

|

41 |

4000X5000 |

|

|

87 |

174 |

|

42 |

4000X6000 |

|

|

96.5 |

193 |

|

43 |

4000X7000 |

|

|

107 |

213.5 |

|

44 |

4000X8000 |

|

|

117 |

235 |

Product Detail Mfoniniyɛ .

Related PRODUCTS