- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

3D didiasogy

Product parameter .

Beae a wofi mu:Hebei .

Waranti: Afe 1 .

Mmoa a wɔayɛ no sɛnea wɔpɛ: OEM, ODM .

Brand din . .

Nhwɛsode no nɔma:2005 .

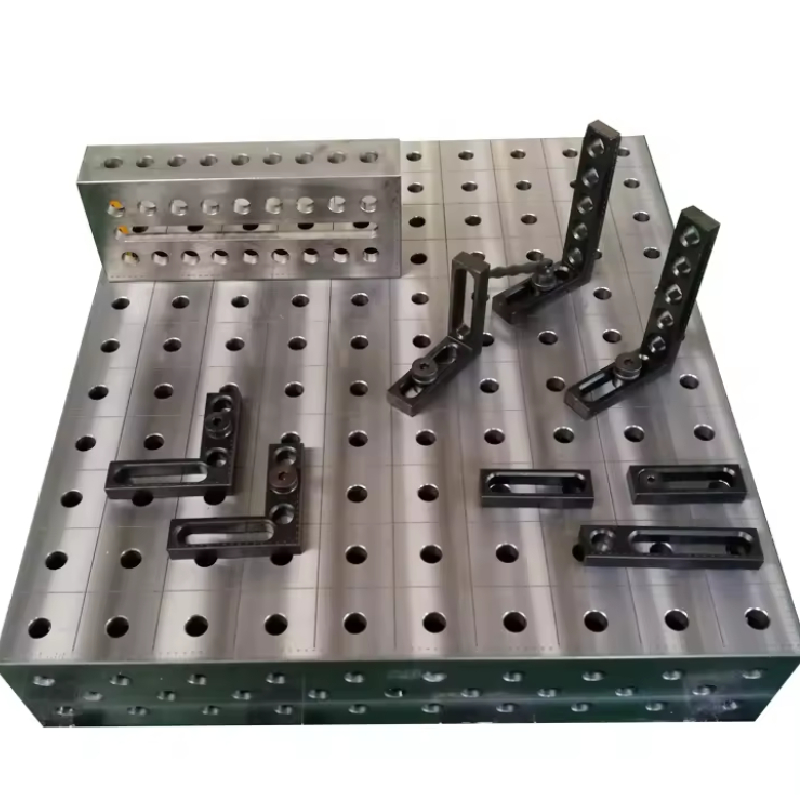

Product Name:3D Welding Platform a Ɛyɛ Fɛ .

Nneɛma: Dadeɛ/Dadeɛ a Wɔagu .

Nneɛma a wɔde di dwuma .

Pore kɛse a wɔde gyina ano -±0.05mm .

Aduru a wɔde yɛ nneɛma a ɛwɔ soro T:Asase a ɛwɔ soro no nitriding .

Flatness:0.02mm/1000mm .

Nneɛma a ɛyɛ mmerɛw:Ra1.6-Ra3.2.

Adeyɛ: CNC Machining .

Type .:Moulding Mia .

Abodin krataa:ISO9001:2008 .

Nneɛma a wɔde kyekyere nneɛma ho nsɛm: Plywood adaka 3d welding pon a nneɛma a wɔde yɛ adwuma OEM HT300 black oxide finish 3d flexible welding table .

Selling units: Ade biako pɛ .

Nneɛma a wɔde ahyɛ mu biako kɛse:100x100x20 cm .

Ne mu duru a ɛyɛ biako pɛ:5000 kg .

Bere a wɔde di kan .

|

Dodow (afã horow .) |

1 – 100 |

> 100 |

|

Bere a wɔde di kan (nna .) |

5 |

sɛ wɔbɛka ho asɛm . |

3D welding pon so .

3D welding platform yɛ welding platform a ɛkɔ anim, platform no .

na wɔkyekyɛ afã anan no mu a ntokuru yɛ 28, a wɔde di dwuma de yɛ nhyehyɛe ne .

3D flexible fixture no, sɛnea ɛbɛyɛ a wobenya gyinabea ne krak a ɛyɛ ntɛmntɛm wɔ adwuma no mu .

Ɛsɛ sɛ wɔde weld di dwuma. Mfaso a ɛwɔ 3D welding platform so no yɛ nea ɛyɛ adwuma yiye, .

pɛpɛɛpɛyɛ a ɛkorɔn, ne ɛho ka a ɛba fam. 3D welding tooling nhyehyɛe ahorow a wɔahyehyɛ no titiriw betumi .

Di customer welding afã horow nyinaa ho dwuma.

Product parameter .

|

3D welding table nkyerɛkyerɛmu krataa . |

|||||

|

D28 Nsɛm a Wɔahyehyɛ . |

D16 nsɛm a ɛtoatoa so . |

||||

|

Nnɔmba . |

Nkyerɛkyerɛmu . |

muduro |

Nnɔmba . |

Nkyerɛkyerɛmu . |

muduro |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

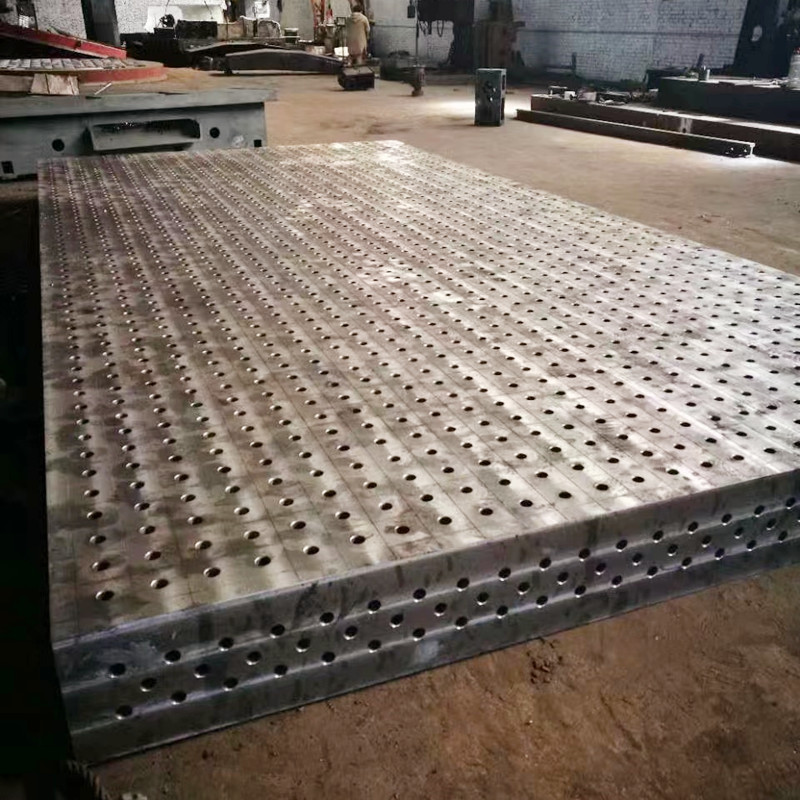

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

Aguade no ho nsɛm .

Components betumi ahyɛ mu wɔ wo paw akyi nea edidi so yi .:

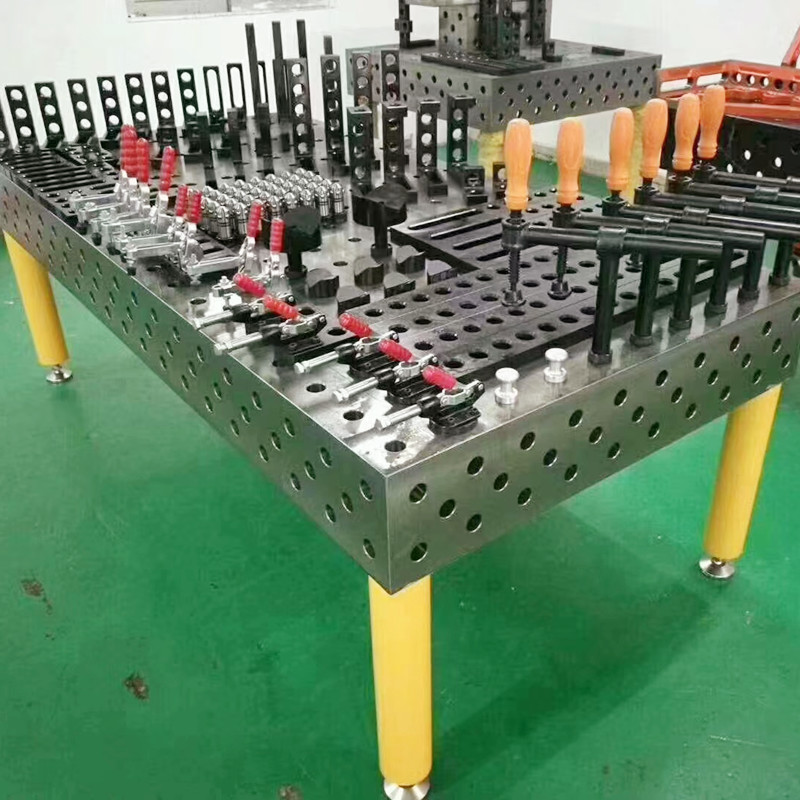

1, Nnwinnade a wɔde boa: U-shaped cube case, l-shaped cube case, angle supporting, ne angle gauge .

2, spare parts a wɔde hwehwɛ baabi a .:

3, Nnwinnade a wɔde kyekyere nneɛma na wosiesie .

4, spare parts a wɔde bɛto mu a ɛyɛ adwuma .

5, nnwinnade a ɛboa .

3D Welding Table 1.2×2.4 1×2 1.5×3 2x4m wɔ wɔ stock cast dade pon ne fixture pon so .

- - Dimensions:1000X1000mm-2000X4000mm

- - Nneɛma anum a ɛyɛ adwuma Wobetumi de ade a ɛma wohu baabi a ɛwɔ no asi so. nso wobetumi atrɛw mu denam ne nnwuma anum a ɛyɛ adwuma no mu biara so.

- - Wɔakyekyɛ ne nneɛma no mu: dade a wɔde yɛ welding tables (Q345) ne casting welding tables (HT300).

- - Wɔakyekyɛ ne tokuru no mu: D28 Series ne D16 Series.

- - diagonal grid: D28 yɛ 100 * 100mm; D16 yɛ 50 * 50mm.

Su

Mmoa a wɔde ma .: Nan, dade a wɔde ayɛ nnua, ne hydraulic lift box, sɛnea wɔhwehwɛ no.

3D welding platform no yɛ amansan nyinaa fixture a wɔayɛ no titiriw ama welded nneɛma a wɔyɛ; Wɔde di dwuma ma welding a ɛyɛ mmerɛw, ɛyɛ nea ɛyɛ mmerɛw, na ɛsono pii wɔ atetesɛm mu welding akwan ho.

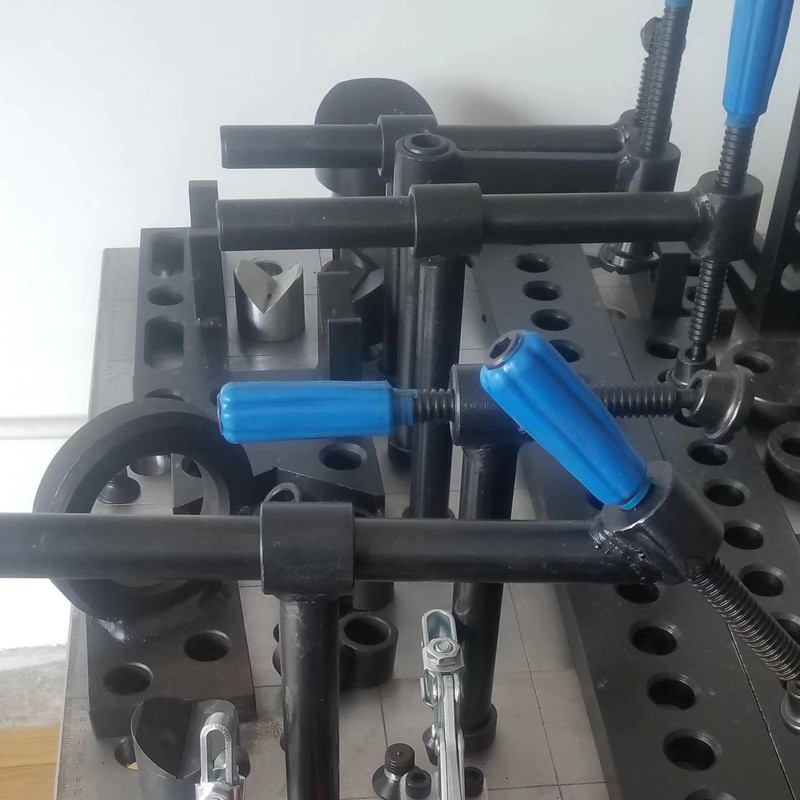

abiɛsa-afã tokuru nhyehyɛe nkabom flexible welding nhyehyɛe nnwinnade.

Nsusuwii abiɛsa .: gyina hɔ ma akwankyerɛ abiɛsa. Mpɛn pii no, fixtures yɛ longitudinal na transverse a enni vertical directions. Asɛnka agua no wɔ akwan abien, na wobetumi de ano anan no adi dwuma de asisi hɔ gyina hɔ, na wɔanya afã abiɛsa a wɔaka abom.

tokuru nhyehyɛe .: Ade titiriw a ɛwɔ saa fixture yi mu ne sɛ efi platform no so kosi nneɛma a wɔde di dwuma no so no, ntokuru a ɛyɛ pɛpɛɛpɛ wɔ hɔ a enni atetesɛm nhama anaa T-slot. Sɛ wɔde pin a wɔde to mu ntɛmntɛm ka ho a, wobetumi ayɛ nhyiam no ntɛmntɛm na ɛyɛ mmerɛw, na wobetumi ayɛ gyinabea.

Nkabom: Esiane sɛ wɔadi kan ayɛ nneɛma a wɔde ka ho nyinaa nti, wobetumi aka abom na wɔayɛ nsakrae wɔ mu sɛnea ade no ahiade te.

Nsakrae a ɛba .: Sɛ wɔde nnwuma a yɛaka ho asɛm wɔ atifi hɔ no di dwuma a, nnwinnade no nyinaa betumi asesa sɛnea nsakrae a aba wɔ ade no mu te. Nneɛma a wɔde si dan mu no betumi adi nneɛma pii anaa nneɛma pii ahiade ho dwuma, na ɛma nneɛma ho nhwehwɛmu ne nkɔso ne sɔhwɛ a wɔyɛ no yɛ ntɛmntɛm kɛse, na ɛma nnipa pii, nneɛma a wɔde yɛ adwuma, ne sikasɛm mu nneɛma pii (nneɛma a atwa yɛn ho ahyia no nyɛ papa na ɛnyɛ nea mframa bɔne pii wom).

Welding .: Saa ade yi yɛ amansan nyinaa fixture a wɔayɛ ama nneɛma a wɔde weld ayɛ no titiriw; Wɔde di dwuma ma welding a ɛyɛ mmerɛw, ɛyɛ nea ɛyɛ mmerɛw, na ɛsono pii wɔ atetesɛm mu welding akwan ho.

Ahwehwɛde titiriw a ɛwɔ anti-rust primer wɔ 3D welding platform so ne: a ɛbata ho yiye wɔ casting no ani, anti rust adwumayɛ pa, adhesion pa a ɛbata soro layer of paint, ne easy construction ne storage.

Nneɛma a ɛwɔ soro a ɛsɛ sɛ wohwehwɛ wɔ 3D welding pon so .

Sɛ worepaw 3D welding table a, ɛho hia sɛ wususuw nneɛma ahorow a ɛma adwumayɛ ne pɛpɛɛpɛyɛ ho kɛse wɔ wo welding nnwuma mu no ho. 3D welding pon a ɛyɛ papa betumi ama nsonsonoe a ɛwɔ nea eye sen biara a wobenya mu aba no nyinaa aba. Nneɛma a ɛwɔ soro a ɛsɛ sɛ wohwehwɛ .:

1. Robust Construction: Ɛsɛ sɛ wɔde nneɛma a ɛkorɔn a ebetumi agyina nnesoa a emu yɛ duru ano ne welding akwan horow a ɛyɛ den no na ɛyɛ 3D welding pon a ɛyɛ den. Hwehwɛ apon a wɔde dade anaa dade a ɛyɛ den ayɛ a wɔayɛ no, na hwɛ hu sɛ ɛbɛtra hɔ akyɛ na agyina pintinn.

2. Modularity: Tumi a wode bɛyɛ wo nhyehyɛe no sɛnea wopɛ na woayɛ nsakrae no ho hia yiye. Modular 3D welding table ma kwan ma wɔde add-ons ne accessories ahorow bom, na ɛma wotumi yɛ wo adwumayɛbea no ma ɛne nnwuma pɔtee hyia, sɛ́ ɛyɛ nsusuwii nketewa a ɛyɛ nwonwa anaasɛ nhyiam akɛse.

3. Precision machining: Sɛnea ɛbɛyɛ a wobenya pɛpɛɛpɛyɛ a ɛsen biara no, ɛsɛ sɛ wɔde mfiri a ɛyɛ pɛpɛɛpɛ na ɛyɛ nneɛma a ɛwɔ 3D welding table no so. Hwehwɛ tables a ɛma grid nsusuwso a ɛwɔ ntokuru ne slots a ɛwɔ ntam kwan pɛpɛɛpɛ, a ɛma ɛyɛ mmerɛw sɛ wɔbɛkyekyere na wɔde adwuma no asi hɔ yiye.

4. Versatile clamping options: Clamping ano aduru a etu mpɔn ho hia na ama wɔahwɛ ahu sɛ ɛyɛ den bere a wɔreyɛ welding no. Ɛsɛ sɛ 3D welding pon a ɛyɛ papa no ma wonya mmeae ahorow a wɔde si so ne nea wɔde kyekyere nneɛma ho, na ɛma wotumi yɛ nhyehyɛe a ɛyɛ mmerɛw na ɛma wotumi kura nneɛma ahorow ne nneɛma akɛse mu.

5. Compatibility ne fixtures: Hwɛ sɛ 3D welding table a wopaw no ne fixTuring nhyehyɛe ahorow hyia. Saa nhyiamu yi bɛma wo tumi a wode bɛbɔ custom setups ntɛmntɛm na ayɛ adwuma yie no ayɛ kɛseɛ, ɛbɛma wo bere na ama adwumayɛ akɔ soro.

. Hwehwɛ pon a wɔde nneɛma a wɔde kata so anaasɛ nea wɔde awie a ɛboa ma adwumayɛbea a ɛho tew no kɔ so yɛ adwuma na ɛma pon no nkwa nna yɛ tenten.

Mfaso a ɛwɔ so sɛ wode 3D welding pon bedi dwuma ama adwuma a ɛyɛ pɛpɛɛpɛ .

Wɔ wiase a wɔde dade yɛ mu no, sɛ wobenya pɛpɛɛpɛyɛ na wɔayɛ no pɛpɛɛpɛ a, ɛho hia kɛse ma nnwuma a edi mu. Nnwinnade a etu mpɔn sen biara a ɛwɔ hɔ ma welders no mu biako ne precision 3D welding table. Ɛnyɛ sɛ saa nnwinnade a ɛho hia yi ma adwumayɛ yɛ kɛse nko, na mmom ɛma adwuma a wɔawie no yɛ papa kɛse nso.

Wɔayɛ 3D welding table a ɛyɛ pɛpɛɛpɛ a ɛwɔ nhyehyɛe a ɛyɛ den a ɛma kwan ma wɔyɛ nhyehyɛe a wotumi sesa no ma ɛne ahwehwɛde pɔtee a ɛwɔ adwuma biara mu no hyia. Wɔtaa de nneɛma a ɛyɛ papa na ɛyɛ ɔfasu no, na ɛhwɛ ma ɛyɛ den na ɛyɛ den bere a wɔreyɛ welding no. Saa pintinnyɛ yi betumi asiw dade afã horow a wɔreyɛ ho adwuma no a ɛbɛkyinkyin anaasɛ ɛbɛkyinkyim, a ɛho hia kɛse na ama wɔatumi akura gyinapɛn ahorow a ɛyɛ pɛpɛɛpɛ a ɛkorɔn mu.

Mfaso titiriw foforo a ɛwɔ 3D welding table a ɛyɛ pɛpɛɛpɛ a wɔde bedi dwuma so ne jigs ne fixtures a ɛkɔ anim a ebetumi agye. Saa pon yi mu pii de T-slot anaa ntokuru a ɛma welders tumi kyekyere nneɛma a ɛwɔ mu no yiye ba. Saa adeɛ yi ho hia ma nnwuma a ɛwɔ afã ahodoɔ pii, baabi a nhyehyɛeɛ a ɛfata a wɔbɛkɔ so akura mu no ho hia. Ne saa nti, asiane a ɛwɔ hɔ sɛ obi bɛyɛ basaa na wadi mfomso no so tew kɛse, na ɛma wotumi yɛ weld a ɛho tew na ɛyɛ pɛpɛɛpɛ.

Bio nso, 3D welding table a ɛyɛ pɛpɛɛpɛ a wɔde di dwuma no betumi ama adwumayɛ akɔ so yiye na ama bere a wɔde yɛ adwuma biara no so atew. Ɛdenam adwumayɛbea a wɔakyerɛ sɛ ɛyɛ adwuma na ɛyɛ adwuma yiye a wɔde bɛma so no, welders betumi de wɔn adwene asi wɔn adwuma no adebɔ ne mfiridwuma afã horow so kɛse sen sɛ wɔde besi nhyehyɛe no so. Saa adwumayɛ a ɛkɔ soro yi ma adwumayɛ kɔ soro na awiei koraa no, mfaso a eye ma nnwumakuw.

Sɛ yɛde rewie a, sika a wɔde bɛto precision 3D welding table mu no yɛ game changer ma obiara a ɔyɛ adwuma wɔ welder a ɔrehwehwɛ sɛ ɔbɛma wɔn nsaanodwuma ayɛ kɛse. Ɛnam sɛ ɛtumi ma ɛgyina pintinn, ɛtumi sesa, na ɛyɛ adwuma yie nti, ɛyɛ adwinnadeɛ a ɛsom boɔ a ɛboa welding adwuma a ɛkorɔn na ɛyɛ pɛpɛɛpɛ. Sɛ́ ebia woyɛ ɔbenfo a ne ho akokwaw anaasɛ obi a onnim hwee wɔ welding afuw mu no, akyinnye biara nni ho sɛ 3D welding pon a ɛyɛ pɛpɛɛpɛ a wode bedi dwuma no bɛma wo nnwuma no akɔ soro akodu ɔfã a edi hɔ no.

Core functions ne mfiridwuma mu dwumadie boɔ a ɛwɔ 3D welding tables .

Storaen 3D welding tables no san kyerɛkyerɛ pɛpɛɛpɛ ne adwumayɛ mu wɔ mfiridwuma welding fabrication mu, yɛ adwuma sɛ versatile modular platforms a wɔayɛ sɛ ɛbɛma adwumayɛ mu gyinabea, fixture integration, ne multi-axis welding adwumayɛ ayɛ mmerɛw. Sɛ́ obi a odi kan a ɔde welding fabrication tables ma no, yɛde ano aduru a ɛka rigidity a ɛkorɔn, configurations a wotumi sesa, ne pɛpɛɛpɛyɛ a wotumi san yɛ bom—ehia ma nnɛyi nneɛma a wɔyɛ a ɛhwehwɛ sɛ welding a enni mu koraa ba no bom.

Precision gyinabea wɔ core no mu .

Wɔ yɛn 3D welding table design no mu no, ɛwɔ afã anum grid a ɛyɛ pɛpɛɛpɛ-mfiri ntokuru (D28 anaa D16 series), a ɛma kwan a ɛnyɛ den a wɔde bata ho a ɛyɛ clamps, angles, ne fixtures a ɛfa soro ani ne afã anan no nyinaa. Saa grid nhyehyɛe yi (100x100mm anaa 50x50mm spacing) hwɛ hu sɛ ɛwɔ gyinabea pɛpɛɛpɛ wɔ ±0.05mm mu, na eyi nsusuwii a ɛwɔ nneɛma a ɛyɛ den te sɛ automotive chassis frames, aerospace brackets, anaa mfiri a ɛyɛ adwuma a emu yɛ duru no hyia. Nea afi mu aba? Welding nhyehyɛe a wotumi san yɛ a ɛtew sɔhwɛ ne mfomso nsakrae so 60%, a ɛho hia kɛse ma mass production wɔ baabi a consistency yɛ nea wontumi nsusuw ho.

Modular flexibility ma fabrication ahiade ahorow .

Yɛn welding fab tables no di yiye wɔ adapability so .:

Multi-platform integration: Wobetumi de bolted abɔ standard sizes (1000x100mm kosi 2000x4000mm) abom denam quick-lock pins so, ayɛ adwumayɛbea a wɔatrɛw mu ama nnwuma a ɛsõ dodo—a ɛyɛ papa ma po so ahyɛn a wɔyɛ anaa kuayɛ nnwinnade a wɔboaboa ano.

Nnwinnadeɛ a ɛnni mu nsakraeɛ: Ɛne welding accessories ahodoɔ pii (U-blocks, T-slots, magnetic clamps), table no ma kwan ma reconfiguration ntɛmntɛm wɔ nnwuma ahodoɔ ntam, twitwa fixture setup time so 50% sɛ wɔde toto atetesɛm fixed-position tables ho a.

Nneɛma a emu yɛ duru a wɔde yɛ adwuma: Wɔde HT300 cast iron anaa q345 dade a ɛwɔ ribbed understructure na ɛyɛe, saa tables yi gyina static loads a ɛkɔ soro kodu 2700kg, a ɛboa mpo mfiridwuma mu nneɛma a ɛnyɛ deflection —ɛsɛ sɛ ɛyɛ ma excavator arm welding anaa crane structure fabrication.

Mfiridwuma mu dwumadie: baabi a pɛpɛɛpɛyɛ du adwumayɛ ho .

Kar Ho Nneɛma a Wɔyɛ .

Fa di dwuma sɛ welding fabrication table a wɔde boaboa kar nipadua nnua ano, hwɛ hu sɛ spot welds no hyia wɔ ±0.1mm mu ma ɛne OEM su gyinapɛn ahorow hyia. Anti-spatter coating option no bɔ ɔfasu no ho ban fi welding debris ho, na ɛtrɛw ɔsom nkwa nna mu wɔ nneɛma a ɛyɛ kɛse a wɔyɛ mu.

Ahunmu & Ahobanbɔ .

Nea ɛho hia ma aluminum alloy structures a emu yɛ hare a wɔyɛ (sɛ nhwɛso no, wimhyɛn engine mounts), baabi a pon no ɔhyew a ɛyɛ den (ntrɛwmu ketewaa bi wɔ welding ɔhyew ase) ne flatness (0.02mm/1000mm) siw dimensional deviation a ebetumi asɛe wimhyɛn ahobammɔ no ano.

Mfiri a emu yɛ duru & nnwinnade .

Go-to ano aduru ma welding bulldozer frames anaasɛ industrial pump casings, aseda a ɛyɛ den adansi ne modular design a ɛfata odd-shaped workpieces denam custom fixture installations.

Nea enti a Storaen 3D welding tables di anim .

Beyond core functions, yɛn tables no yɛ .:

Surface Finish Excellence: Asase ani (RA1.6-RA3.2) hwɛ hu sɛ fixture no kankan no yɛ mmerɛw na ɛne ne ho hyia pɛpɛɛpɛ, bere a nitriding ayaresa a wotumi paw no ma wear resistance a ɛwɔ abrasive welding mmeae no yɛ kɛse.

Wiase Nyinaa Gyinapɛn a Wɔdi So: Wɔagye atom sɛ ISO 9001 ne JB/T7974-99, yɛn 3D welding pon no di amanaman ntam gyinapɛn ahorow a wɔhwehwɛ no ahwehwɛde a emu yɛ den no ho dwuma, na ɛma asomdwoe ba wɔ nnwuma a ɛfa ahye so ho.

Ma wo welding nhyehyɛe no so ne Storaen .

Sɛ́ ebia wuhia welding fab table a ɛyɛ ketewaa a wode bɛyɛ prototyping anaasɛ 3D welding pon kɛse a wode bɛyɛ mass no, Storaen ano aduru ahorow no de pɛpɛɛpɛyɛ, ahoɔden a ɛtra hɔ kyɛ, ne sɛnea wotumi yɛ nsakrae a ɛho hia na ama woakɔ so adi kan wɔ nnɛyi nsusuwii mu no ma. Ɛdenam nhyehyɛe bere a ɛba fam, fixture compatibility a ɛma ɛyɛ kɛse, ne hwɛ a yɛhwɛ hu sɛ wɔbɛsan ayɛ no pɛpɛɛpɛ so no, yɛn tables no dannan welding fi manual, error-prone process mu kɔ adwumayɛ nhyehyɛe a ɛyɛ mmerɛw, a ɛyɛ adwuma ankasa —ɛma wo kuw no tumi ma wɔkyekye yiye, ntɛmntɛm, na wɔde ahotoso a ɛne no nhyia.

Nneɛma a wɔde boa ne ano aduru a wɔahyɛ da ayɛ ama 3D welding tables .

Storaen 3D welding tables no yɛ comprehensive accessory system ne tailored custom solutions, a wɔayɛ sɛ ɛbɛma versatility, precision, ne adaptability ayɛ kɛse ama welding fabrication ahiade biara. Sɛ́ ebia wopɛ sɛ wode nneɛma a ɛyɛ pɛpɛɛpɛ hyehyɛ mu ma ɛyɛ ntɛm anaasɛ woayɛ nsakrae wɔ mu ama nnwuma soronko no, yɛn ayɛyɛde ahorow no dannan wo welding fabrication table no ma ɛyɛ adwumayɛbea a ɛyɛ soronko koraa —a wɔayɛ no sɛnea ɛbɛyɛ a ebetumi adi nnɛyi nneɛma a wɔyɛ no ahwehwɛde a ɛyɛ den no ho dwuma.

Modular accessory ecosystem ma integration a ɛnyɛ den .

Yɛn plug-and-play accessories ma wo welding fab table no dwumadi yɛ kɛse, na ɛma wotumi yɛ nsakrae ntɛmntɛm na ɛyɛ adwuma yiye .:

Mmoa & Leveling Nnwinnade: Dade nan a wotumi sesa a ɛwɔ anti-vibration pads no hwɛ hu sɛ nhyehyɛe a ɛyɛ den wɔ sotɔɔ no fam a ɛnyɛ pɛpɛɛpɛ so, bere a hydraulic lifting systems (100–500mm height range) ma ergonomic positioning yɛ adwuma ma overhead anaasɛ hard-to-reach welds.

FixTuring & Clamping Solutions: Magnetic clamps ahorow, toggle clamps, ne U-blocks (a ɛne D28/D16 hole systems hyia) secure workpieces a ɛwɔ nsusuwii ne akɛse nyinaa, a ntɛm-release mfiri a ɛtew fixture installation bere so 40%. Angled brackets (0–90° adjustable) ne precision squares boa wɔ multi-axis alignment mu, a ɛho hia ma nhyiam a ɛyɛ den te sɛ robɔt nsa anaa ahunmu trusses.

Safety & Protection Add-ons: Anti-spatter coatings (a wɔde di dwuma wɔ pon so) ne splash guards a wotumi yi fi mu no ma nneɛma a asɛe a ɛboaboa ano no so tew, bere a ntama a ɛko tia ɔhyew bɔ grid nhyehyɛe no ho ban fi welding arcs a wɔde di dwuma bere tenten no ho —ɛtrɛw pon no som nkwa nna mu wɔ nneɛma a atwa yɛn ho ahyia a ɛyɛ den kɛse mu.

Amanneɛbɔ Ano Aduru: Wɔayɛ no sɛnea ɛte wɔ w’anisoadehu mu .

Nsusuwii & nhyehyɛe ahorow a wɔayɛ no yiye .

Beyond standard sizes (1000x1000mm kosi 2000x4000mm), yɛyɛ 3D welding tables wɔ amanne kwan so tenten, ne trɛw, ne ne sorokɔ —a nea ɛka ho ne oversized platforms (ɛkɔ 5000x3000mm) ma mfiridwuma-scale nnwuma. Nneɛma a ɛnyɛ kurukuruwa (a ɛyɛ kurukuruwa, L-shaped) ne mmeae a ɛwɔ fam a wɔde si so no ma mfiri titiriw anaa robɔt a wɔde welding yɛ adwuma a wɔde afiri yɛ no, na ɛma wotumi de wɔn ho hyɛ wo nneɛma a wɔyɛ no mu a ɛnyɛ hwee.

Nneɛma a wɔde yɛ adwuma pɛpɛɛpɛ .

Hole System Customization: Yɛ tokuru ntam kwan (sɛ nhwɛso no, 75x75mm ma hybrid grids) anaa kyerɛ metric/imperial thread ahorow (M12, 1⁄2”-13 UNC) ma ɛne fixtures a ɛwɔ hɔ dedaw no hyia, na eyi hia a ehia ma adapter mprɛte no fi hɔ.

Ayaresa a ɛwɔ soro: Paw nea ɛwɔ fam (RA1.6 ma wɔde di dwuma wɔ ɔkwan a ɛfata so) anaasɛ nneɛma a wɔayɛ no yiye kɛse (RA0.8 ma metrology-grade alignment), a nitriding a wopɛ (HV900+) na ama den ayɛ den na woako atia abrasive wear wɔ heavy-duty applications mu.

Nsakrae a ɛfa nnwuma ho pɔtee .

Kar: T-slots a wɔaka abom a wɔde yɛ conveyor belt alignment, a eye ma kar fã welding nkwammoaa a ɛkɔ ntɛmntɛm.

Ahunmu: Non-magnetic stainless steel inserts a ɛbɛma NDT (nsɔhwɛ a ɛnyɛ nea ɛsɛe ade) a ɛyɛ mmerɛw no atumi atwitware bere a wɔreyɛ aluminum aduru welding no.

Marine: Epoxy-coated undersides ma corrosion resistance wɔ nkyene nsu tebea mu, a wɔde abɔ mu ne reinforced corner brackets ma offshore rig component fabrication.

Nsakrae a ɛba ntɛmntɛm & wiase nyinaa mmoa .

Stock Accessories: Clamps, nan, ne leveling nnwinnade dodow no ara de po so hyɛn kɔ wɔ nnɔnhwerew 24 ntam, na ɛhwɛ ma ɛyɛ adwuma kakraa bi ma wɔyɛ nsakrae wɔ nneɛma a wɔyɛ mu.

Custom Lead Times: Wɔde Standard Custom Tables (Nneɛma a Ɛnyɛ Ntini) ma wɔ nnafua 15–20 mu, a wɔde mfiridwuma mmoa a wɔatu ho ama a wɔde bɛsiesie mfonini ne nneɛma a wɔpaw (sɛ nhwɛso no, dade a ɛnyɛ den a wɔde bɛyɛ aduan-grade applications).

Certified quality: Custom 3D welding tables nyinaa kɔ flatness sɔhwɛ a ɛyɛ den (0.02mm/1000mm) ne load-bearing validation, a ISO 9001-compliant calibration amanneɛbɔ ka ho ma traceable quality control.

Bue wo welding fab table no tumi nyinaa .

Storaen’s accessory systems ne custom solutions no, wo welding fabrication table no bɛyɛ nea ɛboro adwuma benkyi so —ɛyɛ platform a wotumi sesa ma nneɛma foforo. Sɛ́ ebia wuhia nneɛma a ɛnyɛ adwuma no mu nneɛma a ɛbɛma woanya mfaso ntɛm ara anaasɛ 3D welding pon a wɔayɛ no sɛnea wopɛ koraa ama adwuma a ɛyɛ nwonwa no, yɛn kuw no de mfiridwuma ho nimdeɛ ne nneɛma a wɔyɛ no ntɛmntɛm bom ma ano aduru a ɛne w’anisoadehu hyia. Ma wo welding dwumadi ahorow no so denam nneɛma a ɛsakra ne nea wopɛ a ɛsakra so —efisɛ wɔ fabrication mu no, pɛpɛɛpɛyɛ yɛ biribiara, na kɛse biako mfata ne nyinaa da.

Nneɛma a ɛwɔ mu .

Anti-rust primer a wɔtaa de di dwuma ne srade a wɔde yɛ aduru. Abɔde mu resin paint. Asphalt a wɔde ayɛ aduru. Phosphate paint, ne nea ɛkeka ho Wɔn adwumayɛ ne sɛnea wɔde di dwuma no gu ahorow. Wɔatew mprɛte a ɛyɛ tratraa a wɔde weld ayɛ no ho. Bere a wɔatwa nhwehwɛmu no awie no. Mpɛn pii no, wɔde anti rust paint gu nneɛma a ɛnyɛ nea wɔde di dwuma anaa nneɛma nyinaa so. Sɛ wɔde di dwuma a, ɛsɛ sɛ yɛte ase yiye sɛ wɔ welding mprɛte a ɛyɛ tratraa a wɔpaw ne nea wɔyɛ mu no, mpɛn pii no, nsaano mfoniniyɛ kwan no yɛ mmerɛw. sikasɛm mu no ɛyɛ mmerɛw na ɛfata ma castings a wɔyɛ no biako pɛ.

- T he adwumayɛ tebea a ɛwɔ welding platform no so. Adwumayɛbea a ɛfata ma mfonini ahorow a ɛko tia rust no gu ahorow. Enti, sɛ ɔpaw a, ɛsɛ sɛ obi te adwumayɛbea a ɛwɔ mprɛte a ɛyɛ tratraa a wɔde weld ayɛ no ase.

- Ɛho nhia sɛ wɔde primer ne topcoat no hyia. Welding mprɛte a ɛyɛ tratraa, de ka primer ho. Na ɛsɛ sɛ wɔde paint gu so. Wɔde topcoats dodow no ara di dwuma bere a wɔayɛ mfiri ho adwuma awie no, enti ɛsɛ sɛ wosusuw adhesion a ɛda primer ne topcoat ntam no ho. Mpɛn pii no, primers ne topcoats a wɔasiesie a wɔde paint nneɛma a ɛte saa ara ayɛ no hyia. Ebia primers ne topcoats a wɔde paint ahorow ahorow asiesie no rentumi nhyia esiane sɛ ɛbata ho denneennen nti. Wontumi ne wɔn ho wɔn ho nnya abusuabɔ pa. Enti, ɛho hia sɛ yɛte sɛnea paint no yɛ adwuma no ase.

- Ɔkwan a wɔfa so yɛ anti-rust primer. Anti-rust primer biara wɔ n’ankasa ɔkwan pa a wɔfa so yɛ ne nea wɔde kata so. Sɛnea ɛbɛyɛ na wɔasi so dua sɛ adwumayɛbea anaa adwumayɛbea no wɔ tebea horow a ɛte saa no, wɔyɛ welded flat plate no sɛnea JB/T7974-99 gyinapɛn no kyerɛ. Wɔyɛ ade no ma ɛbɛyɛ ribbed plate ne box type. Anim a ɛyɛ adwuma no wɔ ahinanan, a wɔde HT200 ayɛ. Anim a ɛyɛ adwuma no gye mfiridwuma a wɔde twitwiw nneɛma ne nea wɔde twitwiw nneɛma, na wobetumi de mfiri ayɛ V-nsusuwii wɔ anim a ɛyɛ adwuma no so. T-nsusuwii. Ntini a ɛte sɛ U ne ntokuru a ɛyɛ kurukuruwa. Long holes, etc. Welding flat plate yɛ flat reference adwinnade a wɔde yɛ adwuma welding, na ɛsɛ sɛ wɔsesa mprɛte a ɛyɛ tratraa no ma ɛne horizontal no hyia sɛnea installation ahwehwɛde ahorow no te. Wɔkyekyɛ adesoa no pɛpɛɛpɛ wɔ mmoa beae biara so. Sɛ wode di dwuma wɔ baabi a ɛhɔ yɛ hyew a ɛyɛ 20 ± 5 °C a, ɛsɛ sɛ wɔkwati wosow.

Product Detail Mfoniniyɛ .

Related PRODUCTS